In the world of elite football, where milliseconds and millimetres can determine the outcome of crucial matches, every detail matters. For Liverpool’s adidas-affiliated players, this attention to detail extends all the way down to their boots—quite literally. The German sportswear giant has perfected the art and science of creating bespoke football boots that are tailored to each player’s unique physiology, playing style, and personal preferences.

In an exclusive look inside adidas’ state-of-the-art facilities in Herzogenaurach, Germany, we discover the fascinating journey from initial foot scan to match-ready boot—a process that takes just 10 days from start to finish. This is the story of how cutting-edge technology, decades of expertise, and meticulous craftsmanship combine to give Liverpool’s stars the perfect foundation for their performances at the highest level.

The Anatomical Reality: No Two Feet Are Alike

Before delving into the intricate process of boot creation, it’s worth understanding why such customization is necessary in the first place. According to Michael Haley, senior manager for athlete product excellence at adidas, the experts in his department can count on one hand the number of athletes they’ve assessed with truly identical feet.

This remarkable statistic underscores a simple but often overlooked truth: every footballer’s feet are unique. Variations in toe height, arch length, forefoot width, heel shape, and countless other factors mean that off-the-shelf solutions, no matter how well-designed, will never provide the optimal fit for elite athletes operating at the margins of human performance.

“Comfort has a correlation with performance,” Haley explains, succinctly capturing the philosophy that drives adidas’ approach to athlete footwear. When a player is comfortable in their boots, they can focus entirely on their game—free from distractions like pressure points, instability, or restricted movement. In a sport where confidence and feel for the ball are paramount, this comfort translates directly into better performances on the pitch.

For Liverpool players, this means that their boots aren’t just equipment—they’re precision instruments calibrated specifically to their feet, playing style, and individual needs.

The World of Sports: Where Innovation Meets Tradition

The journey to create these bespoke boots begins in one of two locations. Liverpool players affiliated with adidas can make the trip to the company’s global headquarters in Herzogenaurach, Germany—a sprawling campus aptly named the “World of Sports.” This facility represents the pinnacle of sports technology and innovation, housing everything from design studios to biomechanics laboratories.

Alternatively, for the convenience of players managing packed schedules during the season, Michael Haley and his team of specialists can bring their futuristic-looking technology directly to Liverpool’s AXA Training Centre. This flexibility ensures that assessments can be conducted without disrupting training schedules or requiring international travel during crucial periods of the campaign.

Regardless of location, the process remains the same, utilizing the same cutting-edge technology and benefiting from the same expertise that adidas has developed over decades of working with the world’s elite athletes.

Step One: The 3D Scanning Revolution

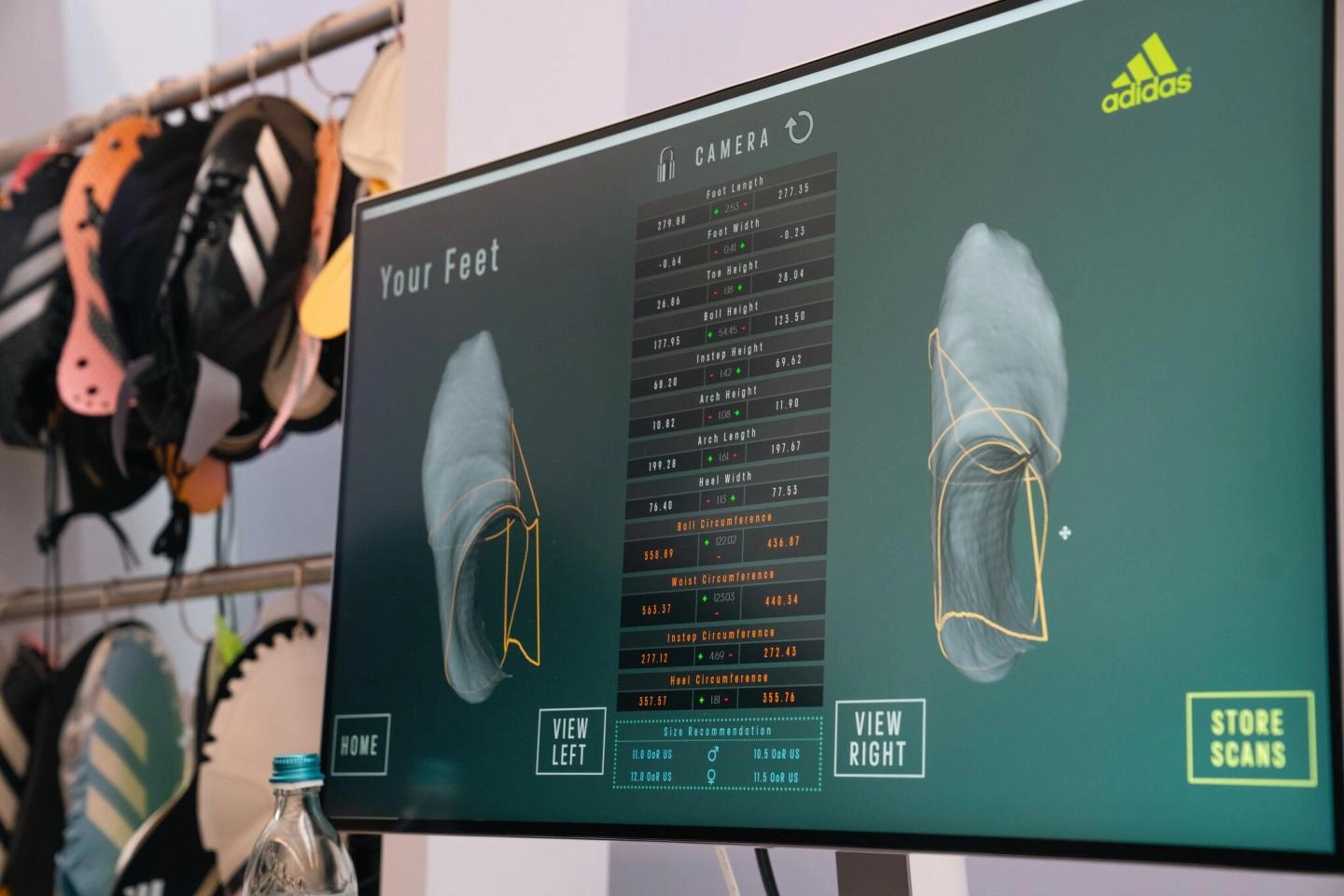

The customization process begins with what might look like something from a science fiction film: a comprehensive 3D scanning system that captures every contour, curve, and dimension of a player’s feet.

This isn’t a simple measurement exercise. The scanning technology captures thousands of data points across the entire foot structure, creating a detailed three-dimensional map that includes measurements such as:

- Toe height and length variations across all five toes

- Forefoot width at multiple points

- Arch length and height to understand the foot’s natural curvature

- Heel dimensions including width and shape

- Instep measurements crucial for boot closure and fit

- Ankle positioning relative to the foot structure

Each scan takes only moments to complete but generates a wealth of information that forms the foundation of the entire customization process. This digital footprint becomes the blueprint from which everything else flows, ensuring that the final product matches the player’s anatomy with millimetre precision.

The beauty of this 3D scanning approach is that it captures not just size but shape—understanding that a player with a size 9 foot might have completely different proportions than another player wearing the same size. It’s this level of detail that separates truly custom footwear from simply selecting a size from a range.

Step Two: Understanding Weight Distribution and Movement Patterns

After the static measurements are captured, the assessment moves to dynamic analysis. Players step onto a sophisticated foot-pressure mapping device that reveals how they distribute their weight across both feet—both when standing still and during movement.

This technology uses thousands of sensors to create a pressure map that shows which areas of the foot bear the most force, where pressure concentrations occur, and how weight shifts during various movements. For footballers, this information is invaluable because:

- Balance and stability insights: Understanding weight distribution helps optimize boot construction to support a player’s natural stance and movement patterns.

- Pressure point identification: Areas experiencing excessive pressure can lead to discomfort, blisters, or even injury over time. The boot design can be adjusted to alleviate these pressure concentrations.

- Performance optimization: Knowing how a player naturally moves allows designers to reinforce specific areas of the boot that experience the most stress, ensuring durability where it matters most.

- Injury prevention: In collaboration with Liverpool’s medical team, this data can be used to design boots that help mitigate injury risks, whether that’s supporting a previous injury site or compensating for biomechanical factors that might increase injury susceptibility.

The collaboration with Liverpool’s medical staff is particularly crucial here. The club’s sports scientists, physiotherapists, and medical professionals provide valuable context about each player’s injury history, current fitness status, and any specific considerations that should inform the boot design. This holistic approach ensures that the boots aren’t just comfortable but also contribute to player welfare and longevity.

The Design Philosophy: Snug Fit Meets Personal Preference

Armed with comprehensive anatomical and biomechanical data, the adidas team moves into the design phase. Here, science meets personal preference, as modern football boots are typically designed to be snug-fitting—a trend that has dominated professional football in recent years.

Players increasingly prefer this close-fitting style because it provides:

- Maximum ball control: Less space between foot and boot means better touch and feel for the ball

- Enhanced striking sensation: Players can better sense ball contact for improved passing and shooting accuracy

- Reduced internal movement: A snug fit minimizes foot slippage inside the boot, improving stability and responsiveness

- Superior agility: Tighter-fitting boots move more naturally with the foot during quick changes of direction

However, “snug” is not a one-size-fits-all concept. Each player searches for their own perfect fit to varying degrees. Some prefer an extremely close fit that feels almost like a second skin, while others want a touch more room in specific areas like the toe box or around the ankle. The beauty of the adidas customization process is that any personal preference can be accommodated.

Want more room around the toes but a tighter fit through the midfoot? Done. Need extra support around the ankle but flexibility in the forefoot? No problem. This level of customization ensures that each player gets exactly what they need to perform at their best, rather than having to compromise with a standard fit.

Making It Personal: The Aesthetic Touch

Once the performance and comfort elements are finalized, the process moves into a realm that’s equally important to many players: personalization and aesthetics. While the technical specifications ensure the boot performs perfectly, these personal touches make it truly theirs.

Common customization options include:

Family Connections: Many Liverpool players choose to inscribe the names of partners, children, or other family members on their boots. These deeply personal touches serve as constant reminders of loved ones and can provide motivation during challenging matches.

National Pride: Flags representing a player’s home country are popular additions, allowing athletes to carry their national identity onto the pitch, even when representing their club.

Meaningful Dates and Numbers: Significant dates—birthdays, anniversaries, or career milestones—often find their way onto custom boots, creating wearable mementos of important moments.

Photographic Etching: Perhaps most impressively, adidas’ manufacturing technology has advanced to the point where actual photographs can now be etched onto boots. This cutting-edge capability allows players to literally wear images of loved ones, meaningful places, or inspirational symbols during matches.

These aesthetic customizations might seem purely cosmetic, but they serve an important psychological function. In the high-pressure environment of elite football, these personal touches can provide comfort, confidence, and connection—factors that, while intangible, contribute to a player’s mental state and, by extension, their performance.

The Scheinfeld Factory: Where Tradition Meets Innovation

After all the data is gathered, measurements are taken, and designs are finalized, everything is sent to adidas’ made-to-measure factory in Scheinfeld, Germany. This facility holds special significance in the company’s history, as it’s the same factory where adidas’ legendary Copa Mundial boots—one of the most iconic football boot designs ever created—are still manufactured to this day.

The choice to produce custom boots in this particular factory is symbolic and practical. It represents a bridge between adidas’ storied heritage and its cutting-edge present, where traditional craftsmanship meets modern manufacturing technology. The workers in Scheinfeld possess decades of collective experience in boot construction, understanding the nuances of leather working, stitching, and assembly that can only come from years of dedicated practice.

In this facility, each custom boot is constructed with meticulous attention to detail, following the precise specifications derived from the player’s assessment. The combination of automated precision and skilled craftsmanship ensures that every pair meets the exacting standards required for professional-level play.

The Boot Portfolio: Variety for Every Surface and Style

Throughout a typical season, adidas creates four distinct colourways of boots for each player. These aren’t just aesthetic variations—they represent different boot models designed for various playing styles and preferences.

Currently, adidas’ flagship football boot franchises include the iconic Predator and the speed-focused F50 models, both of which are worn by numerous Liverpool players across both the men’s and women’s teams. Each model offers distinct characteristics:

The Predator: Known for its textured strike zones and emphasis on power and control, the Predator is favored by players who prioritize ball manipulation, striking accuracy, and commanding presence in midfield or attacking positions.

The F50: Designed with speed in mind, the F50 features lightweight construction and streamlined design elements, appealing to wingers, forwards, and any player whose game relies on explosive acceleration and agility.

For each colourway and model, players typically receive four pairs per quarter, carefully divided between:

- Two pairs with soft-ground (SG) studs: Designed for wet or muddy conditions commonly encountered in British football, these boots feature longer, often metal-tipped studs that provide superior traction in soft ground.

- Two pairs with firm-ground (FG) studs: Suited for drier, firmer pitches, these boots have shorter, more numerous studs that work better on harder surfaces without compromising ankle stability.

This allocation ensures players always have the appropriate footwear for whatever conditions they encounter, whether facing a rain-soaked evening at Anfield or playing on a sun-baked pitch during pre-season tours.

Players who regularly feature for their national teams typically go through even more boots, as international fixtures, tournaments, and training camps add to the wear and tear on their footwear. For these athletes, adidas adjusts the supply accordingly, ensuring they’re never caught without match-ready boots regardless of their schedule.

The Remarkable 10-Day Turnaround

Perhaps the most impressive aspect of this entire customization process is not the technology involved, nor the precision of the final product, but rather the speed at which it all happens. From the initial assessment to receiving match-ready boots, the entire process takes just 10 days.

Consider what happens in that timeframe:

- Day 1: Player assessment with 3D scanning and pressure mapping

- Days 2-3: Data analysis, design finalization, and collaboration with medical staff

- Days 4-8: Manufacturing at the Scheinfeld facility

- Days 9-10: Quality control, shipping, and delivery

This rapid turnaround is crucial in professional football, where players’ needs can change quickly due to injuries, discomfort with current boots, or simply the desire to try a different model or configuration. The ability to go from “I need new boots” to “I’m wearing them in a match” in less than two weeks is a remarkable achievement in custom manufacturing.

The Competitive Edge: Why Customization Matters

In an era where football matches at the highest level are often decided by the smallest margins, the advantages provided by perfectly fitted, customized boots cannot be overstated. Consider the cumulative effect over a 90-minute match:

- Thousands of touches: A midfielder might touch the ball 70-100 times per match. Even a one percent improvement in touch and feel multiplies significantly.

- Countless movements: Players cover 10-13 kilometers per match with hundreds of sprints, changes of direction, and jumps. Boots that fit perfectly and support natural movement patterns reduce fatigue and injury risk.

- Mental confidence: Knowing that your equipment is optimized specifically for you provides psychological reassurance that allows players to focus entirely on their performance rather than worrying about their feet.

For Liverpool, operating at the highest levels of domestic and European competition, these marginal gains can be the difference between winning and losing titles. The club’s partnership with adidas ensures that players have access to this technology and expertise, providing them with equipment that matches their ambitions.

Conclusion: The Future of Football Footwear

The process of creating customized boots for Liverpool’s players represents the current pinnacle of sports equipment technology. Yet, as impressive as it is, this is likely just the beginning. As 3D scanning becomes even more sophisticated, manufacturing techniques advance, and materials science evolves, the boots of tomorrow will be even more precise, even more comfortable, and even more tailored to individual athletes.

For now, Liverpool’s adidas-affiliated players enjoy the benefits of boots that are crafted specifically for their feet, down to the millimetre—a level of personalization that would have seemed impossible just a generation ago. From the initial scan at either the World of Sports in Herzogenaurach or the AXA Training Centre, through the data analysis and design phase, to the skilled craftsmanship at the historic Scheinfeld factory, every step of the process is focused on one goal: giving players the perfect tool to perform at their absolute best.

In a sport where margins are measured in centimetres and seconds, having boots that fit perfectly, feel comfortable, and inspire confidence isn’t just a luxury—it’s a necessity. And for Liverpool’s stars, adidas ensures that this necessity is met with extraordinary precision, expertise, and care.

The next time you watch a Liverpool match and see a player execute a perfectly weighted pass, strike the ball with precision, or accelerate past a defender, remember that their performance is built on a foundation of technology, craftsmanship, and customization—all delivered in an impressive 10-day window from measurement to match day.

🔴Find the Latest News on Player Ratings | Transfers | Prematch | Postmatch

Thank you for your continued support, and let’s cheer Liverpool on to success in the upcoming match. Your thoughts are always welcome in the comments section. For further insights, you may explore the official Liverpool FC website by clicking here.

YNWA (You’ll Never Walk Alone)!

The Liverpool FC Times Team

LiverpoolFCTimes.com